THE ALLIMAND GROUP WINS THE PRESTIGIOUS ORDER OF A MACHINE FOR THE FUTURE EURO BANKNOTES....

THE ALLIMAND GROUP WINS THE PRESTIGIOUS ORDER OF A MACHINE FOR THE FUTURE EURO BANKNOTES….

THE ALLIMAND GROUP WINS THE PRESTIGIOUS ORDER OF A SPECIAL PAPER MACHINE, INTENDED TO MANUFACTURE THE PAPER SUPPORT FOR THE FUTURE EURO BANKNOTES….

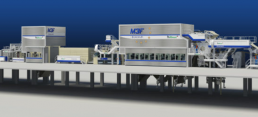

The ALLIMAND Group, designer and manufacturer of paper & nonwovens machines, renowned for its continuous innovation strategy, won the order for the new paper machine for the production of the security paper required for the printing of Euro banknotes. This machine, which is currently being installed at the EUROPAFI mill in Vic-le-Comte (Puy-de-Dôme), a European public fiduciary center, will go into production at the end of 2017.

Banknote paper production: a very high added value machine for a well-known institution

A banknote, by definition, needs to be particularly resistant to aging, manipulations and tearing or counterfeiting. The euro is known to be the most secure banknote in the world, with 10 apparent security features, including holograms, magnetized inks and secret signs, plus a complex encryption of banknotes and a watermark. Made exclusively of highly refined cotton pulp, the future banknote must fulfill all security and inalterability conditions.

“Paper money is a strong symbol of the power of a country and can offer extreme levels of sophistication. We, the ALLIMAND Group, are very proud in to have won the contract for a machine for such a prestigious institution. In France we are usually more present on machine rebuilds”, explains Franck RETTMEYER, CEO of the Group.

Continuous adaptability and reactivity

The mechanical assembly (piping and wiring) of the future paper machine, with a width of 2.55 meters and a length of about 100 meters, is almost complete. The ALLIMAND group has demonstrated its ability to manage a turnkey contract.

“For this machine, we have not only had to supply all of the machine auxiliary equipment but also the DCS – Distributed Control System, for which ALLIMAND carried out the programming and the electrical power supply part” explained the two Project Engineers, Christine PIEGAY and Christophe TRIOULEYRE. In addition, adaptations had to be made during the project in order to allow the installation of security control devices linked to security paper-making and in particular to the Euro.

Since January, the phases of parts delivery and machine assembly succeed each other in order to ensure minimum storage on site and optimized machine assembly time. A complete testing phase of the machine will take place in June and manufacturing will start over the summer.

An overall investment of more than 75 million euros

The total investment of the Vic-le-Comte (63) paper mill, in various equipment, covers 75 million euros. The aim of EUROPAFI, the ALLIMAND Group’s customer, is to double the production capacity and to manufacture around 50% of the paper needed for the annual issue of Euro banknotes in Vic-le-Comte. In the long term, the site must supply several printers in the Eurozone.

ALLIMAND GROUP LAUNCHES NEW TECHNOLOGY “S4 HYDRAULIC HEADBOX”

ALLIMAND GROUP LAUNCHES NEW TECHNOLOGY “S4 HYDRAULIC HEADBOX”

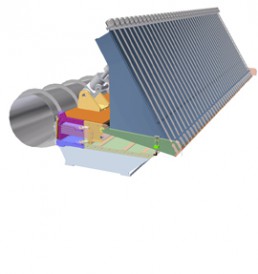

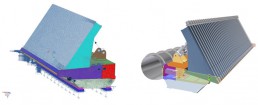

THE ALLIMAND GROUP, DESIGNER AND MANUFACTURER OF PAPER MACHINES AND NONWOVENS, RECOGNIZED FOR ITS CONTINUOUS INNOVATION STRATEGY, HAS JUST LAUNCHED A NEW HYDRAULIC HEADBOX* NAMED S4, WHICH IS CHARACTERIZED BY HIGH TECH TECHNOLOGY. FOCUS ON THIS KEY PART OF THE PAPER MACHINE, WHICH MEETS THE MANUFACTURING NEEDS RANGING FROM CONVENIENCE PAPERS AND PACKAGING TO SPECIALTY PAPERS.

An evolution in response to market productivity requirements

“The new rebuild projects of existing machines require the evolution of paper types, quality improvement or capacity increase,” explains Dr Simon CENA, General Manager of ALLIMAND GROUP. “When reconstructing paper machines, priority is given to the most compact equipment which can be installed with minimum auxiliary equipment and enable an optimized balance between the benefits and investment”.

A new “high performance” version of the hydraulic headbox

Based on these contextual elements, the ALLIMAND Group has initiated the development of a new S4 version of its hydraulic headbox, with the objective of fulfilling the following criteria:

- Compact design and simplified construction.

- Hydraulic performance maintained for the entire production speed range, optimum formation ensured.

- High-performance basis weight profile control by dilution, allowing individual control of orientation and basis weight profile.

- Complete and easy access to the different parts of the headbox in contact with the pulp for cleaning operations which are essential for many specialty grades

1st operational launch on the packaging market

This new S4 hydraulic headbox ALLIMAND is characterized by a highly developped technology, optimized compactness, balance between benefits/investment and its design taking into account the needs of the operators of production. In conclusion, the objectives set for the development of the new ALLIMAND hydraulic headbox S4 have been achieved and the first examples have recently been put into service in the field of packaging.

* The headbox is an element of the paper machine which ensures a uniform distribution of the pulp.

ALLIMAND INTERWEB

ALLIMAND INTERWEB

THE ALLIMAND GROUP OFFICIALLY GETS A FOOTHOLD IN THE USA, THANKS TO THE STRATEGIC MERGER AND ACQUISITION OF GLENS FALLS INTERWEB – GFI

A few months ago, the project to acquire a company based in the United States matured…

It’s done! The ALLIMAND Group, a designer and manufacturer of paper and nonwoven machines, has just officially signed the acquisition of GLENS FALLS INTERWEB (GFI), a recognized leader in nonwoven products in the United States. Thanks to its financial base and expertise in the design and building of non-woven paper machines and highly technical processes, the ALLIMAND Group thus consolidates, with the takeover of GFI, its positioning on all nonwoven products on the five continents.

A Strategic Technological Acquisition

“The acquisition of GFI, a company well-known and recognized in the United States as a specialist in high-tech nonwoven products (1), is a development opportunity for ALLIMAND, enabling us to strengthen our technology and know-how on fiberglass or carbon and ceramic veil machines, and therefore reach new customers,” says Franck RETTMEYER, Chairman & CEO of the ALLIMAND Group. This merger is part of the continuity of an order for a nonwoven machine in the United States, delivered in 2016 for a large international group, leader in its market.

A refocusing of activities on nonwoven machines initiated since 2008

2008, marked by the financial crisis, the irreversible development of @ media and communication, the planned slowdown in investment in China and Asia, reinforced the ALLIMAND Group’s decision to refocus on highly value-added paper. In 2010, the investment of a nonwoven pilot machine in the United States enabled ALLIMAND to sign major contracts and complete its portfolio with orders for nonwoven long-fiber machines installed worldwide (Germany, France, Spain, England, United States, China).

The conquest of a new market: the North American continent

Less than 10 miles are currently separating the ALLIMAND Group nonwoven pilot machine from the company GFI INTERWEB, located on the outskirts of the city of Albany, New York State. “This synergy will allow us to conquer new customers and increase the representation of the range of ALLIMAND machines in North America and in Canada,” continues Franck RETTMEYER.

More information: www.allimand.com / www.gfinterweb.com

(1) Non-woven high-tech products: fiberglass materials and sails, carbon fiber webs, ceramic fiber materials, nonwoven synthetic fibers enrich the existing range of ALLIMAND nonwoven products, namely: Liquid filtration (tea bag, coffee pods), car filtration (air, fuel, oil), wipes and hygiene, specialties (overlay, wallpaper, battery separators, high porosity Plug Wrap … etc).

ALLIMAND leading up to the ATIP 2016 conference

ALLIMAND LEADING UP TO THE ATIP 2016 CONFERENCE

PRIOR TO THE 2ND MEETING OF THE PAPER UNION ASSOCIATION ATIP 2016 SHORTLY TAKING PLACE IN GRENOBLE

Interview with Franck RETTMEYER, Chairman & CEO of ALLIMAND, Designer & Manufacturer of paper machines and nonwoven since 1850

Mr. RETTMEYER you are working flat out at the end of this year, with prestigious contracts, particularly the paper machine which will manufacture banknotes for EUROPAFI / BDF … What are your success factors? Is the economic recovery on a global scale or is this level of activity specific to the ALLIMAND Group ?

Franck RETTMEYER : The recovery doesn’t only concern the ALLIMAND group. In 2008 – 2009, we decided to refocus on paper with very high added value. This focus has allowed us to take orders including that of EUROPAFI and complete our portfolio with nonwoven machines built worldwide. This conjunction of elements, driven by a market that invests, and also the strong packaging market, allows us to take orders and turn effectively at “full throttle”.

For next year, your order book looks healthy with the order a new nonwoven machine in Asia, a special paper machine in China, and the delivery of the paper machine for EUROPAFI. So Asia is the Eldorado for paper machine manufacturers ?

Franck RETTMEYER : Firstly, this nonwoven machine in Asia represents a new success for ALLIMAND, and in addition to other paper machine orders taken a few months ago. China is not the Eldorado; on the contrary, the Asian continent has become less and less accessible these last few years. However, the Chinese have a particular demand for machines and highly technical processes, which ALLIMAND can meet.

The new S4 hydraulic headbox – the latest ALLIMAND development.

Your merger-acquisition project in the UNITED STATES is starting to take shape … Can you tell us more and tell us the direct impact it will have on the products you offer, your market and finally in terms of employment in the area…?

Franck RETTMEYER : This project will materialize by the end of the year. It will allow ALLIMAND to strengthen its high-tech machinery and therefore reach new customers through the acquisition of new technologies. Given the slowdown in investments in Asia and China, it was essential to find new markets, and the North American market is particularly appropriate for this type of machine.

We have already delivered a nonwoven machine in the USA this year, to a large international group. This merger and acquisition is a continuation of this order. An appointment will be made by the end of the year, the time to finalize contracts which are complicated to draw up, considering the US laws.

ATIP 2016: What message would you like to get across in the framework of the 2nd meeting of the Paper Union Association, as a captain of industry ? What place can the industry hope to occupy in today’s French economy…?

Franck RETTMEYER : A technical association is always representative of the companies it represents. The ATIP manages to gather together paper makers and manufacturers. We can only encourage them to continue on this path. For a manufacturer like ALLIMAND, it is the opportunity to present its references, its success with its customers and new products. This year we will present our new S4 hydraulic headbox – the latest ALLIMAND development – for which the first commercial success was recorded in Thailand.

This question concerning the place of industry in the French economy is more political. Certainly, until recent years, consumption was favored at the expense of the creation and manufacture of products on French soil.

We need a strong industry, strong agriculture which will also help develop the service sector. To reverse the trend in unemployment and boost investment in France will require more time in a country whose growth is almost zero…

CONGRES ATIP : 8 – 9 November 2016

GRENOBLE – Alpes Congrès

OPEN FORUM with Franck RETTMEYER, Chairman & CEO of the ALLIMAND Group

OPEN FORUM WITH FRANCK RETTMEYER, CHAIRMAN & CEO OF THE ALLIMAND GROUP

UPDATE ON ECONOMIC ACTIVITY MID-YEAR “BUSINESS IS ABOUT TAKING RISKS…!”

In an unstable international context of the political, economic and financial situation, the corporate world is looking for answers to the daily questions concerning its future. However, more than ever, Franck RETTMEYER, CEO of the ALLIMAND Group, designer and manufacturer of paper and fibrous materials machinery since 1850, continues the growth dynamic. He highlights the significant increase in order intake of 15 to 20% since the beginning of the year. Let’s take stock of the Group’s economic activity, mid 2016.

A LEVEL OF PARTICULARLY SUSTAINED ACTIVITY FOR THE ALLIMAND GROUP

Since 2014, France has lost its position as the fifth largest world economy, dethroned by the United Kingdom. The country struggles to emerge from the crisis, despite a rebound in GDP growth in 2015 (1.2%), supported by the recovery of public and household consumption. It is estimated that growth will be of 1.4% in 2016, below its pre-crisis level.

What is the level of activity of the Group ALLIMAND?

Franck RETTMEYER : We recorded this year a significant increase in our order books intake of 15 to 20 %. These orders include paper machine rebuilds for the packaging and board industry and complete paper machines in France, Asia and the United States. These orders mainly concern special paper machines, paperboard machines and nonwoven machines, two sectors that invest regularly worldwide.

JOB CREATING GROWTH…

Will this strong growth create jobs within the ALLIMAND Group?

Franck RETTMEYER : Yes and no. We have set up a 4 year employment plan, consisting of recruitment of new skills and qualified personnel. More specifically, we regularly hire each year paper engineers, process engineers, mechanics and technicians to operate the “latest generation” machining centers. A lot of candidates come from the Rhône-Alpes area, but we also hire people from all geographical origins.

ZOOM IN ON A GROWING NICHE MARKET: SOUTH AFRICA…

You have just returned from a trip in South Africa… As President of SYMOP (Union of production and technology manufacturers for the paper industry), you organized two conferences in South Africa to meet the papermakers of this country. Can you tell us more…?

Franck RETTMEYER : Whether in Durban for the first conference or in Johannesburg for the second, more than 140 paper manufacturers accepted the invitation from the French manufacturers, in a friendly learning atmosphere, to learn about the French offer. A great success, with the added advantage of the strong involvement of Madam the Ambassador of South Africa.

BUSINESS IS ABOUT TAKING RISKS…!

Franck RETTMEYER : In the world’s history, it is the first time that we have ever had such an opportunity: that of having the ability to market our products all over the world…! The future is for those with audacity. But the law based on the precautionary principle, no longer allows the French to start up businesses. It kills the spirit of initiative. Our best talent leaves France because they want to express themselves, where they have opportunity, without being thrashed by taxes. Now starting up means taking risks! A manufacturer must take risks. The group ALLIMAND continues to invest in the renewal of its machine tools park in Rives in Isère (38) and to develop new products for the paper industry.

What are the prospects for the ALLIMAND Group for the coming years?

Franck RETTMEYER : We have a major external growth project for paper with very high added value. It will complement the geographical coverage of the ALLIMAND group, present today in Europe and Asia. This information will be announced in preview in September.

ALLIMAND's new website

NOUVEAU SITE INTERNET ALLIMAND

ALLIMAND Group undergoes a 360° digital turnaround with the launch of its new website www.allimand.com

Aware of the impact digital marketing and social media have on a company today (communication, marketing, sales, customer relations), the ALLIMAND Group, designer and manufacturer of paper and fiber mat machines since 1850, undergoes a complete digital turnaround with the launch of its new website.

Shaping, structuring the outline of its new corporate strategy, the Group, on the lookout for the latest web 3.0 trends, clearly defines a new vision of the customer relationship.

Focused around the base line “AGILITY FOR…”, ALLIMAND’s new website demonstrates -if needed- its ability to adapt to the market and its customer’s needs in “start-up mode”, that is to say, acting in real time to deal with changes. “Being agile means responding, reacting. Not remaining trapped in the concepts, organization methods and structures of the past: “To think out of the box”. The goal is to always remain in control whatever the circumstances,” argues Fabrice GILET, ALLIMAND Sales Director.

The new website: in response to strong market development

From the home page, the emphasis is put on the ALLIMAND Group’s organization and communication orientated towards excellence and high level expertise and innovation in R&D. “Beyond the objective of presenting a clearer picture of the company’s activity, we hope that every customer can relate to the website and position the ALLIMAND Group as a partner,” he adds. “Optimizing a wider communication towards all market players, whatever their status, function or position in the company, became essential in the context of strengthening our marketing strategy”.

A 360° turnaround for ALLIMAND: refined graphic design, easy and intuitive navigation

Very customer orientated, consistent with the needs of the papermaker, the new website aims to be more accessible. “Paradoxically, given the complexity of our business and the large size of our machines, we sought to simplify things with a clean and clear web design, use of generic visuals and easy and intuitive navigation. The new website is refined, dynamic and reassuring” says Philippe COUDURIER, Industrial Designer and artistic advisor for the design of the website.”

A responsive design, a multilingual website

Professional showcase of high added value products, the website naturally has a responsive design, allowing users to consult on their computers, smartphones and tablets. The site will be translated initially into Spanish and Chinese, and then German and Japanese, to meet the requirements of the main target markets of the Group.

ALLIMAND present at IDEA 2016 in Boston

ALLIMAND PRESENT AT IDEA 2016 IN BOSTON

COME AND JOIN US AT OUR BOOTH # 452

ALLIMAND, key manufacturer for the nonwoven market, will be present at IDEA 2016 in Boston from the 2nd to the 5th of May 2016.

You will be able to meet us at the booth 452 where you will be able to find out more about our skills, experience and references in the classic, speciality and hi-tech nonwoven sectors:

- ASupport for customers in their product development,

- Pilot tests for establishing samples for tests and marketing and commercial certification,

- Tailor-made production lines,

- Optimisation and long term monitoring of the production line operational characteristics.

We look forward to welcoming you.

Loris Baz, MotoGP

LORIS BAZ, MOTOGP

Having sponsored Loris BAZ for the last two years for the Superbike World Championship, with a promising future, Allimand renews its contract with the young rider for the MotoGP World Championship, the premier class of GP motorcycle racing.

This year is a year of change for Loris BAZ, a new team with a new bike and new rules which will allow him to express his talent. Talent is something the young rider is not lacking. The midseason trials proved that we can count on him to get good results for the 2016 season.

New order in Thailand

NEW ORDER IN THAILAND

INDUSTRIAL INNOVATION: ALLIMAND WINS AN ORDER IN THAILAND FOR A “LATEST GENERATION” HYDRAULIC HEADBOX

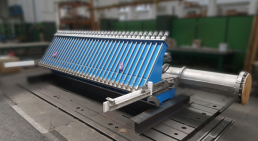

Early this year, the ALLIMAND Group, French designer and manufacturer of paper machines for the paper industry, Rives (38 – Isère – Rhône-Alpes), has just taken a new order for a latest generation hydraulic headbox, to replace one of the existing headboxes of its Asian customer.

The customer, ASIA KRAFT PAPER Group Co, Ltd, is a leading Thai actor in the packaging sector. Highly integrated, it has several processing plants and a paper production plant for packaging, fluting & liner papers on the outskirts of Bangkok.

With a clear technologically competitive advantage, ALLIMAND was quickly able to turn the decision in its favour and convince ASIA KRAFT PAPER to once again put their trust in the industrial SME.

The Asian Customer: ASIA KRAFT PAPER Co, Ltd Group

ALLIMAND is a long-standing partner of the ASIA KRAFT Group, including having delivered and started up the largest of the 2 paper machines in 2002; a complete production line of corrugated base paper with a capacity of 150,000 t/year.

It’s more recently on the oldest paper machine, that ALLIMAND machinery was requested by the ASIA KRAFT Group, with the delivery and commissioning in 2014 of a new FP ALLIMAND headbox for the top wire of the 2 wire part paper machine.

“Latest generation” hydraulic headbox design

Encouraged by the excellent results obtained with this ALLIMAND “SII” headbox on the top layer of this machine, ALLIMAND naturally became a candidate for the replacement of the bottom headbox, decided by the Thai group ASIA KRAFT PAPER Co, Ltd. For this new headbox, ALLIMAND offers the latest evolution S4 of its hydraulic headbox, a concept particularly suitable for flow rates of the lower layer.

A clear competitive “high performance” technological edge

All features (see box below) allow ALLIMAND be able to offer its customers a high-performance hydraulic headbox at a perfectly managed price, capable of covering a wide range of applications on different types of paper.

These technical and economic specificities fulfil all criteria which will enable the ALLIMAND hydraulic headbox S4 to quickly obtain a list of references, after the registration of the order for the group ASIA KRAFT PAPER Co., Ltd., Thailand…

Specificities and technical advantages of the “latest generation” ALLIMAND hydraulic headbox

ALLIMAND Hydraulic headbox S4 is characterized by an extremely compact design, without any compromises being made in respecting the hydraulic criteria which allow ALLIMAND hydraulic headboxes to deliver a perfectly homogeneous spray and an optimum deflocculating effect.

As part of a machine rebuild, its lateral feeding system allows it to be installed on machines with very little space, minimizing the cost of modifying equipment on the approach flow system.

The ALLIMAND hydraulic headbox S4 can be supplied with or without the system of basis weight control by dilution and is suitable for a wide range of papers. It has easy access for cleaning operations by tipping the rear feeding system and if necessary, by the lateral opening of the flanges.

ATIP 2015

ATIP 2015

A GOOD TURNOUT FOR THE GALA EVENING

A skilfully produced light show set off the machinery in the workshops and set the tone for the exceptional gala evening held at the Allimand headquarters in Rives. A warm welcome for the 250 guests and perfect organization; everything to make for an enjoyable evening.

The gala, like in 2010, was held on the Allimand premises and was a huge success: a good turnout, excellent tempo and a gypsy band to generate a lively atmosphere. This year, Hugues Leydier, Daniel Gomez and Virginie Batais were joined by the journalist and presenter, Jérôme Bonaldi, who having participated in the convention opening ceremony and run the round-table conference, naturally played a part in the evening ceremony as well. As usual, the Progress Trophies and Palmes Innovation awards were presented.

Meetings of the papermaker’s union

MEETINGS OF THE PAPERMAKER’S UNION

AN ENGAGING MEETING

Rejuvenated and revitalized, the Atip convention surprised everyone with its work spaces, technical workshops and conferences led by papermaker and supplier duos. Following the rugby match that took place during the last convention, this year an unforgettable evening was hosted by the Allimand group; a sound and light show, with more than 240 people taking part, an increased participation rate of more than 35%.

The next edition is already scheduled for 2016, the 8th and 9th of November in Grenoble.

4th industrial revolution

4TH INDUSTRIAL REVOLUTION

INDUSTRY OF THE FUTURE

Prior to the 68th ATIP “the Paper Industry Technical Association” convention 24-26 November – GRENOBLE

INTERVIEW with Franck RETTMEYER, Chairman & CEO of the group ALLIMAND, designer and manufacturer of paper machines (Rives-38)

The upcoming Paper Union meetings bringing together paper makers, suppliers, technical centres and engineering schools (68th ATIP “the Paper Industry Technical Association” convention) will be held in Grenoble from the 24th to the 26th November. In this framework one of the themes which will be discussed is “the industry of the future in view of the 4th industrial revolution: can we access digital progress? Myth or reality?”.

Interview with Franck RETTMEYER, chairman & CEO of the group ALLIMAND, French designer and manufacturer of paper machines in Rives (38) and President of SYMOP, Paper Group.

Today we are going through a transitional period particularly with regards to energy, digital technology, ecology, organization and society in general. It is having an impact on all industrial production activities. As the Chairman of SYMOP, paper machine group, can you tell us what the paper making industry context data is today? What is the demand? What are the challenges?

As a representative of manufacturers, equipment manufacturers and suppliers of the paper making industry (Chairman of SYMOP – paper group), what interests us is to participate in the modernization of the industrial tool for our paper making customers in France, Europe, America, Asia and the rest of the World. An incredible world market where our companies can sell anything, where they want and to who they want. The only restriction being limited geographical areas or local conflicts, wars but also embargoes, a weapon used more and more by the Americans for example. An incredible market is at our, manufacturers and suppliers, disposition owing to the globalization of the market.

This future development will bring with it the following consequences:

- The development of industrial internet and online objects creating a permanent dialogue between customers, manufacturers and suppliers,

- The means of design which are offered to our companies,

- The means of real time control and analysis with therefore improved traceability,

- The management of flows and the balance between production and customer needs,

- Automated production and the development of robots in our factories to carry out part of the production, production storage with autonomous AGVs, the associated software. In 10 years time, 40% of jobs will be carried out by robots instead of humans! A real issue in our society which will have an impact mainly on tertiary jobs such as banks and administrative type public sector jobs,

- Manufacturing using 3D printers, an astonishing tool soon to be within everyone’s reach,

- Maintenance by remote and predictive maintenance systems.

How does the ALLIMAND group position itself? What are the main objectives to be followed in priority? Optimisation of your competitiveness, accessing new markets, new processes…? What is your main objective and allocated budget?

ALLIMAND’s priority is the geographical presence of the group and the development of new products. The budget set aside for these two priorities is between 5 and 10% of our annual turnover depending on the years, which is a lot.

What working method have you put in place concerning the future industrial development plan at ALLIMAND?

Firstly, observation to understand this major change. Secondly, we need to put the necessary measures in place to revolutionise our organisation and order processing capabilities. Our action plan will be developed over a long term period.

What message do you want to send out about the industry of the future? What do you think are the key success factors?

An incredible technological offer is at our companies’ disposition, the most extraordinary lever being hyper connection and robots. The drawback being the evolution of jobs not qualified with hyper automation and connection, a societal problem that could be resolved by a universal subsistence income (a basic allowance given with no conditions) like in Finland. Is society ready to go in this direction, and in particular, France? That’s the question.

EXTRACT OF THE ATIP CONVENTION PROGRAMME (24-26 November GRENOBLE)

25th November:

4pm – 5.45pm: GRENOBLE / ALPEXPO: : Round-table conference held by Jérôme BONALDI: “Industry of the future in view of the 4th industrial revolution”. Can we access digital progress? Myth or reality? Nine perspectives to be explored to push the limits of our industry: doubts or hopes?

7.45pm: RIVES / ALLIMAND: :Official ATIP gala evening with the presence of 250 actors of the French and European papermaking profession and local political representatives.

Pap'Argus conference

PAP’ARGUS CONFERENCE

HOW TO BECOME AND REMAIN A LEADER IN FRANCE?

Photo Valérie Lechiffre – Magazine “La Papeterie” – ENP Publishing Group

It’s Jean-Pierre Brice Capitalmind,managing partner, who ran the round-table conference dedicated to the French leaders of the paper making industry. What qualities are needed to succeed and what actions need to be taken? In his opening statement, Jean-Pierre Brice mentioned the well-known Mittlestand, the middle market companies which are Germany’s industrial backbone. According to him, in order to become a leader, several criteria must be fulfilled: “Higher than average results in its activity sector, investment and a leadership on target markets”. The companies that participated in the round-table conference fulfil part or all of these criteria. “Furthermore, their shareholders are largely family and, for two of them, they are run by women”, observed Jean-Pierre.

The participants brought together were :

- Sylvie Casenave-Pere, Chairwoman of Posson Packaging

- Simon Cena, Managing Director of d’Allimand

- Nathalie Chapusot, Managing Director marketing /sales and e-commerce delegate for Raja

- Antonio Monteiro, Managing Director “FCR” of Paprec

- Jean-Marie Nusse, Managing Director delegate of Exacompta-Clairefontame

- David Schisler, Chairman of Schisler Packaging Solutions

The vision of the paper machine manufacturer Allimand, was also very clear. Simon Cena highlighted the main assets of the company which is based just outside of Grenoble : “Its independence (with 62% of shareholders being family members), development keeping with market evolution, charismatic leaders, choice, very early on, large-scale exports – in Europe, Asia, North America and tomorrow, we hope in South America – technological know-how and services”. However, the company has chosen to keep the manufacturing of its machines in France. Finally, it meets the needs of traditional and high value added paper making markets (nonwoven, cigarette paper, etc).

SOTIPAPIER

SOTIPAPIER

ALLIMAND STRENGTHENS ITS PRESENCE IN THE NORTH AFRICAN MARKET BY DELIVERING A NAOS SHOE PRESS TO SOTIPAPIER PAPER MILL, TUNISIA

It was in September 2014 that the Tunisian group SOTIPAPIER placed an order with the company ALLIMAND for the rebuild of the paper machine No. 2 at their mill in Belli.

This order came from the close contact established between the two companies. ALLIMAND had the opportunity to conduct a comprehensive analysis of the operation of the machine 2 in order to offer SOTIPAPIER a coherent investment project focusing on rebuilding the press section and the dryer part.

For the SOTIPAPIER Group, this investment involved the production capacity expansion for kraft paper, increasing the gross output of the paper machine no 2 and improving its efficiency and overall performance. The good prospects of the kraft paper market in Tunisia and neighboring countries, coupled with the excellent position of SOTIPAPIER in this sector made this investment a major issue for the group. The trust put in ALLIMAND to carry out this project enhanced the expertise of the French Company in the field of wrapping paper and reinforced its cultural and linguistic proximity with its Tunisian production site environment.

To overcome the main bottlenecks of the paper machine and improve its energy efficiency, ALLIMAND undertook a complete rebuild of the press section by streamlining the sheet path, refurbishing some of the existing equipment and by mounting an ALLIMAND NAOS shoe press with a linear pressure of 1200kN/m.

This equipment, ideal for wrapping paper, increases the dryness of the sheet before it is transferred to the dryer section. This reduces sheet breaks and widely optimizes the steam consumption in the dryer part.

With certain existing elements of the dryer part being obsolete and inefficient, ALLIMAND replaced all doctor, siphon and steam box assemblies.

Based on the principle of a turnkey project, this order included, in addition to the reconstruction equipment of the press section and the dryer part, all the necessary auxiliary equipment for the correct running of the machine: hydraulic system, control system, piping, wiring.

The project also included the complete installation of all equipment provided, supervision and start-up as well as comprehensive training to familiarize operators with this totally new equipment.

Another important part of this order involved a large gantry crane which was designed and installed by ALLIMAND to enable the assembly and maintenance of the shoe press. The mass of which, far exceeded the capacity of the existing lifting equipment. A problem such as this is classic in shoe press installation projects on average sized machines situated in old buildings. However the pitfall was entirely solved by ALLIMAND who implemented a comprehensive and reliable solution for the maintenance team, enabling them to operate this new equipment in the best possible conditions.

In June 2015, as scheduled, the machine was stopped 14 days for the installation and commissioning of the equipment supplied, the gantry crane having previously been installed.

The sheet was engaged in the new press section quicker than initially planned. This result reflects the excellent day-to-day cooperation between the SOTIPAPIER and ALLIMAND teams.

After the start up, the optimisation of production conditions was quickly palpable. The average daily speed increased largely due to the higher dry content of the sheet at the outlet of the press section, the increased drying efficiency in the dryer part, but mainly due to the reduced number of paper breaks.

At the same time, the specific steam consumption decreased, this being a direct consequence of the change of siphons and steam boxes and higher dry content.

Following the machine start-up, the SOTIPAPIER operators will now become familiar with the new production requirements, while having the security of being assisted remotely by ALLIMAND specialists if needed. Indeed, a link allows an ALLIMAND control specialist to control all parameters of the new equipment from a distance and perform troubleshooting in the case of anomalies undetected by the mill personnel.

On this basis, the SOTIPAPIER group will strengthen its position on its market and has the target of an identical project for the second paper machine at the Belli mill, the paper machine n° 3.

AMES, new subsidiary in China

AMES, NEW SUBSIDIARY IN CHINA

“ALLIMAND SHANGHAI”: OPENING OF THE FIRST SUBSIDIARY OF THE ALLIMAND GROUP IN CHINA

After more than 25 years of presence in China, the ALLIMAND Group has consolidated its foothold in Asia and opened its first subsidiary in China!

Present in China since the late 1980s, the ALLIMAND Group, designer, manufacturer of paper machines for the paper industry, recently officially opened its new subsidiary “ALLIMAND SHANGHAI” managed by Mr. Laurent VILLAIN. This fully independent subsidiary will meet its development ambitions in Asia, given that China represents 30 to 60 % of total turnover, according to order figures….

Strengthening ALLIMAND’s presence in China

“Already more than 20 ALLIMAND complete paper machines are operated on Chinese soil, not to mention rebuilt machines,” explains Franck Rettmeyer, ALLIMAND Chairman & CEO. The opening of the “ALLIMAND SHANGHAI” subsidiary serves several purposes. The first is naturally to assist ALLIMAND’s commercial activity, responding to the increased demand for services required by its customers. «Exchange on site with competent partners is a definite competitive advantage,” says Franck Rettmeyer.

Optimizing the efficiency of ALLIMAND’s services

The second goal is naturally to respond using the local language and professionalize the services offered, through the hiring of senior Chinese interlocutors, trained within the ALLIMAND culture. “Being able to take Chinese orders, especially spare parts and services associated with our paper machines allows us to charge directly in RMB, in response to requests from our customers,” continues Franck Rettmeyer. The team is already on site and consists of five people, including a French paper industry engineer wishing to settle in China with his wife.

Strengthening implantation in a strategic town: Zhejiang Province (Shanghai)

The choice of location remains strategic. ALLIMAND set up it’s new subsidiary in Shanghai because of the considerable establishment of papermakers in this area. This paper “Silicon Valley” gathers all the plants specialized in the production of paper with very high added value.

Complying with Chinese culture, the new ALLIMAND Group offices have all the necessary facilities (auditorium conference rooms, private meeting rooms…) to receive not only Chinese customers, but also foreign prospects that cross China. Contracts initiated by Chinese contractors and others for whom ALLIMAND has the ability to position itself as a potential supplier.

“The coming months and years will allow us to consolidate our presence, to acculturate our Management and to get used to working with foreign subsidiaries,” concluded Franck Rettmeyer, confident about the capacity and the managerial skills of his teams.